Page 6 - AKL_Brosch_InnovationAward20_22

P. 6

MEMBERS OF THE PROJECT TEAM

_Dr. Boris Regaard (Team Representative)

_Dr. David Schindhelm

_Dipl.-Ing. Winfried Magg

_M.Eng. Hendrik Meidert

_M.Sc. Alexander Schmid

_Dr. Steffen Keßler

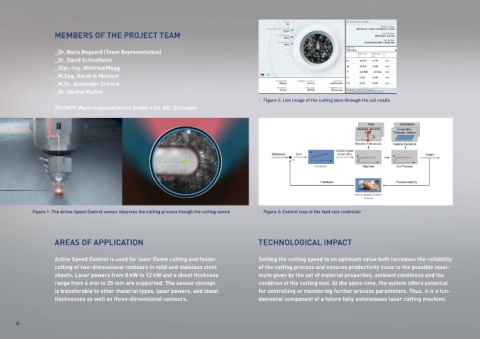

> Figure 3: Live image of the cutting zone through the cut nozzle

TRUMPF Werkzeugmaschinen GmbH + Co. KG, Ditzingen

> Figure 1: The Active Speed Control sensor observes the cutting process though the cutting nozzle > Figure 2: Control loop of the feed rate controller

AREAS OF APPLICATION TECHNOLOGICAL IMPACT

Active Speed Control is used for laser flame cutting and fusion Setting the cutting speed to an optimum value both increases the reliability

cutting of two-dimensional contours in mild and stainless steel of the cutting process and ensures productivity close to the possible maxi-

sheets. Laser powers from 8 kW to 12 kW and a sheet thickness mum given by the set of material properties, ambient conditions and the

range from 4 mm to 25 mm are supported. The sensor concept condition of the cutting tool. At the same time, the system offers potential

is transferable to other material types, laser powers, and sheet for controlling or monitoring further process parameters. Thus, it is a fun-

thicknesses as well as three-dimensional contours. damental component of a future fully autonomous laser cutting machine.

6